Welcome to

On Feet Nation

Members

-

GRAHAM MULFY Online

-

rimeton454 Online

-

Tim Online

Blog Posts

Top Content

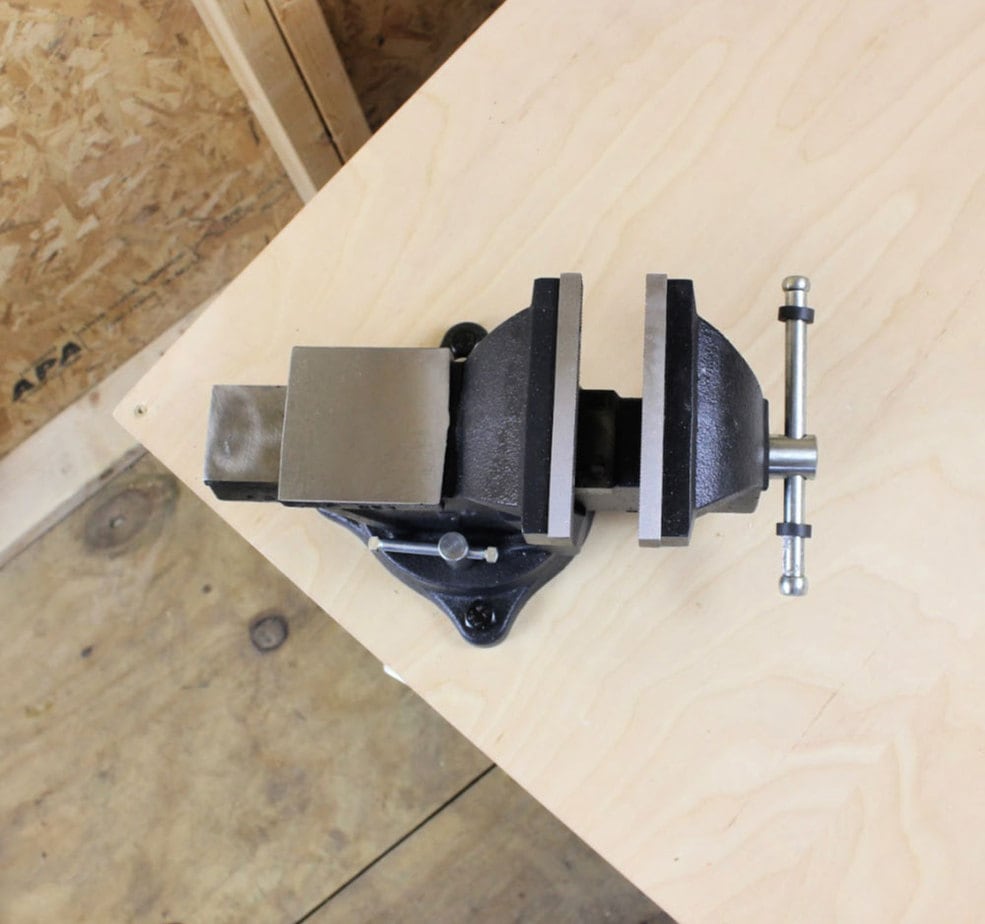

7 Things You Should Not Do With bench vice uses

150mm Heavy Duty Bench Vice - Stanley Tools - An Overview

There aren't a lot of other uses for an end vise, as many materials will protrude into the workshop if clamped into one. Not only does each design of bench vise have specific applications, elements such as jaw width, quick-release, and swivel likewise make a substantial distinction in how well a vise will function in your shop.

The most typical product utilized for bench vises is cast iron. It's exceptionally tough and thick, permitting you to apply a lot of securing pressureimportant for mechanical jobs like eliminating persistent hardware or pressing bushings into automotive parts. Cast iron vises are also ideal to utilize as an anvil hammering surface area.

Some Known Factual Statements About Products : Vices - Gripwell Forgings & Tools

heavy duty bench vice specification

heavy duty bench vice specification

They can deform a bit under extreme pressure, nevertheless, therefore they tend to be cheaper. Woodworking vises do not need a lots of pressure to secure boards and workpieces in place, so steel is more than adequate for a front vise or end vise. Note that producers utilize PSI (pounds per square inch) as the measurement of the strength of their bench vises.

PSI ratings of 30,000 or more are enough for a lot of workshop jobs. It's also crucial to keep in mind that many of the very best bench vises have replaceable jaws. This is an excellent function due to the fact that the jaws' grippy surface areas can use down in time, impacting their capability to grab hold of a workpiece.

Unknown Facts About Everything You Need To Know About Bench Vises... - The ...

Jaw width describes the length of the vise's securing surface area. Small vises can have jaw widths as little as 3 inches, making them appropriate for light-duty jobs and repair work. Big vises can have jaw widths as broad as 10 inches, which offers a lot of surface location for securing big, durable tasks in location.

Woodworking vises tend to have extremely large jaws to promote as much securing surface as possible. These wide surfaces help avoid positioning too much pressure on a little location, which could squash or mar the wood's surface. Jaw openingthe range between the jaws when the vise is fully openedis a crucial consideration, as it figures out how wide of a product you can Homepage secure in your vise.

Little Known Facts About The Best Bench Vises Of 2022 - Bob Vila.

bench vice uses

bench vice uses

Woodworking vises like front- and end-mounted vises will have bigger jaw openings for clamping broad boards in place. It's not uncommon to find a woodworking vise with a jaw opening of more than 10 inches. Throat depth in both bench vises and woodworking vises describes the range from the top of the jaw to the top of the screw system that tightens up the vise.

Throat depth is essential, especially when edge planing wide boards or welding broad pieces of steel. The bigger the throat depth, the much easier it is to clamp these large materials toward their centers, providing more stability and holding strength while permitting you to use more utilize or weight. Generally speaking, the larger the vise, the deeper the throat depth.

Reviews For Bessey 4 In. Heavy-duty Bench Vise With ... Can Be Fun For Everyone

For example, rotating the jaws out of the method permits you to get a much better angle on the anvil surface area, which can make a big distinction when you're trying to strike or bend something to shape. Rotating also allows you to clamp a piece in location, and after that spin it to change the vise's angle instead of stooping over to see the back of the workpiece.

© 2024 Created by PH the vintage.

Powered by

![]()

You need to be a member of On Feet Nation to add comments!

Join On Feet Nation