Welcome to

On Feet Nation

Members

Blog Posts

Top Content

A Short Outline on CNC Flat Machines

A flat machine, just characterized, is a cnc machine apparatus to assist with cutting various profiles in spinning steel or wood work pieces. A standard machine comprises of an accuracy machined bed or base with a drive component along with a headstock toward one side and a supporting tail at the back. The work piece is held in a bad habit like grasp in the headstock and pivoted quickly around its own hub. A suitable machine instrument is then brought into play against the work piece what cuts the expected profile.

There are two sorts of machines - the flat machine and the upward machine. The classification is intended to recognize machines with even or vertical work piece direction. The even machine is wildly utilized in high accuracy machining tasks.

The flat machine is accessible in different sizes, plans, power evaluations, and levels of mechanization. These reach from small scale, seat top watchmakers machines to enormous, completely mechanized PC Mathematically Controlled (CNC) machines. The even machine is transcendently utilized in cutting weighty plate or ring-like machine leaves behind huge distance across and the machine is generally utilized in the handling work of numerous enterprises including elastic, mining, railroad hardware assembling, and auto creation - among others.

There are two primary kinds of level machines - carpentry machines and steel working machines. Wood work machines are naturally the less difficult of the two - however the functioning standard of the two machines is something very similar.

The CNC even machine series is created in congruity with homegrown and global norms. It is for the most part of a smaller design fit for plentiful functionalities, fast, accuracy and so forth It very well might be said that most CNC Machines are old manual machines that have gone through a change to CNC.

The attributes of a CNC flat machine are a 45 degree incline bed and complete watchman cover and oil and water spillage stoppage. The greasing up oil and cooling fluid are disconnected from each other with discrete oil water grooves. The CNC flat machine series consistently utilizes high inflexibility axle structure. Most parts falling off a CNC Machine will be barrel shaped and even. The even machine is flexible and can be utilized to cut round and hollow shapes from square stock or cut elaborate profiles like extravagant table legs, light stands, pens, and chess pieces. Accuracy designing parts like motor parts, circular joints, clinical hardware, and airplane parts can likewise be turned on flat machines. Indeed, practically all steel and wood items which element shoulders, tightens, grooves, or other mind boggling profiles can be handily done on these machines.

Oddly, various designing studios have no CNC machining and are reluctant to embrace new advancements. Albeit the advantages of CNC turning for quality and accuracy are by and large comprehended and broadly acknowledged, the choice to move over to CNC turning is being opposed by designing work retailers.

This is basically because of some broadly common misinterpretation that CNC innovation is confounded and will require exceptionally prepared software engineers to foster turning programs. Notwithstanding all proposals obstruction, the change will unavoidably come. A shop can't remain and make due in business today except if the proprietors surrender their worries and move to CNC.

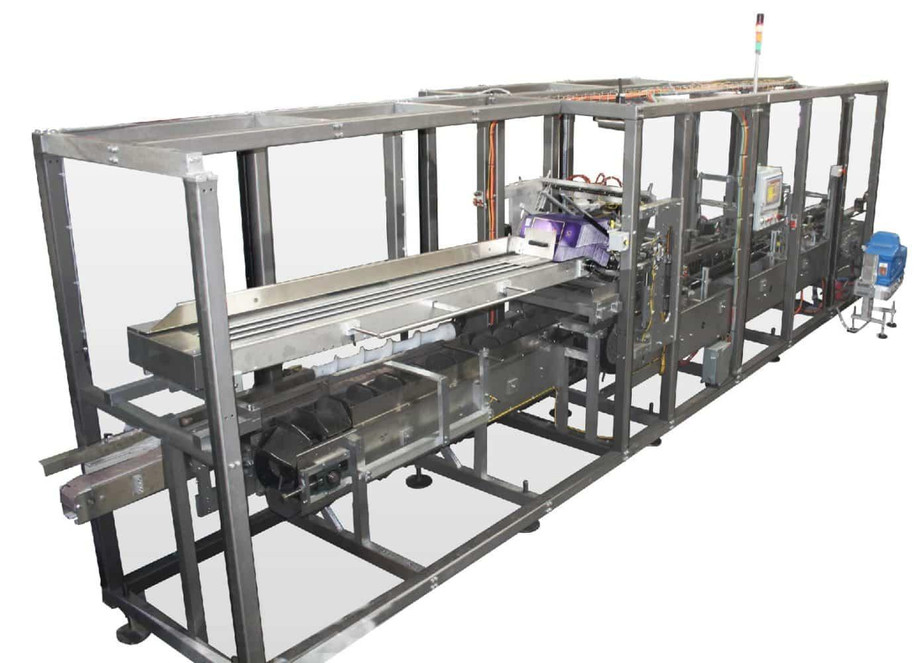

For More Info:-Bottle Case Packing

© 2024 Created by PH the vintage.

Powered by

![]()

You need to be a member of On Feet Nation to add comments!

Join On Feet Nation