Welcome to

On Feet Nation

Members

-

Jack Miller Online

-

Lima Online

-

jack452 Online

-

Galaxy Club Online

-

V2Soft Online

-

jack Online

-

-

-

Thomas Shaw Online

-

-

Harry Online

-

Blog Posts

Top Content

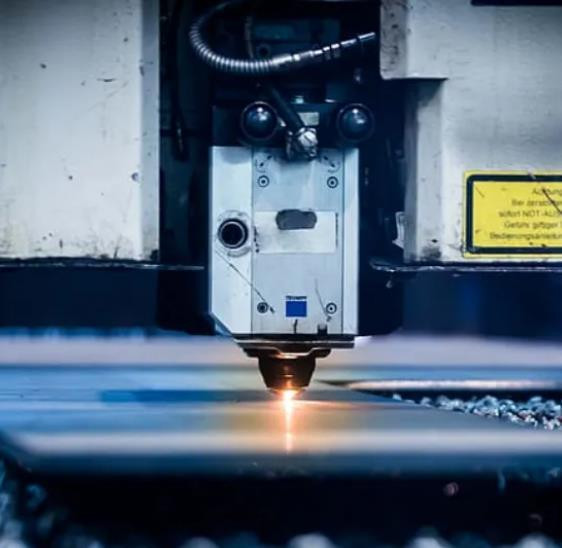

The Benefits of Metal Laser Cutting

Metal laser cutting is a modern technology used in many industries for fabricating metal parts and components. It offers numerous advantages over traditional methods of cutting, such as sawing or shearing. In this article, we will discuss the benefits of metal laser cutting.

Precision and Accuracy

One of the key advantages of metal laser cutting is its ability to produce precise and accurate cuts. Laser cutters use a highly focused beam of light to cut through metal with extreme precision. This allows for complex shapes and designs to be cut with tight tolerances, ensuring a perfect fit for the final product. Additionally, laser cutting is highly repeatable, so identical parts can be fabricated quickly and efficiently.

versatility

Metal laser cutting can be used on a wide variety of materials and thicknesses. This versatility is due to the fact that laser cutters can adjust the intensity and focus of the beam to suit the material being cut. Common materials that can be cut using a laser cutter include steel, stainless steel, aluminum, brass, titanium, and copper. Additionally, laser cutting can be used on thin or thick materials, allowing for the fabrication of components of various sizes and complexities.

Cost-effective

While the initial cost of purchasing a metal laser cutting machine may be high, the technology ultimately proves to be cost-effective. This is due to its efficiency and accuracy, which reduce waste and scrap material. Additionally, laser cutting is faster than traditional cutting methods, allowing for faster production times and reduced labor costs. This all adds up to a faster turnaround time and increased profitability.

Flexibility

Metal laser cutting is highly flexible. Unlike traditional cutting methods, laser cutting can be used to cut complex shapes and patterns. This versatility is due to the fact that laser cutters are controlled by software, allowing for the easy modification of cutting patterns and designs. Additionally, laser cutting can be used to engrave or etch metal, adding more value to the final product.

No tool wear

Traditional cutting methods, such as sawing, shearing, or punching, require the use of physical force and a tool to cut through the metal. This can result in the wear and tear of tools, which can be expensive to replace. Metal laser cutting, on the other hand, uses a non-contact process, which means there is no physical force on the cutting tool. As a result, there is no tool wear, reducing maintenance costs and increasing the lifespan of the machine.

Safe and Environmentally Friendly

Metal laser cutting produces minimal waste and creates no harmful chemicals, fumes, or gases. This makes it a safe and environmentally friendly cutting method. Because of the precision of the laser, the amount of scrap material produced is limited compared to traditional methods. Additionally, there are no cutting fluids, coolants, or lubricants needed, further reducing the environmental impact of the process.

For More Info:-

© 2024 Created by PH the vintage.

Powered by

![]()

You need to be a member of On Feet Nation to add comments!

Join On Feet Nation