Welcome to

On Feet Nation

Members

Blog Posts

Leopard Miracle Honey: Unveiling the Truth

Posted by freeamfva on April 29, 2024 at 11:12pm 0 Comments 0 Likes

Leopard Miracle Honey, a product often marketed for sexual enhancement, has recently come under scrutiny. But what exactly is it, and why should you be cautious?To get more news about lida daidaihua, you can visit herbal-hall.com official website.

The Controversy

Hidden Ingredient: The Food and Drug Administration (FDA) has issued a public… Continue

Top Content

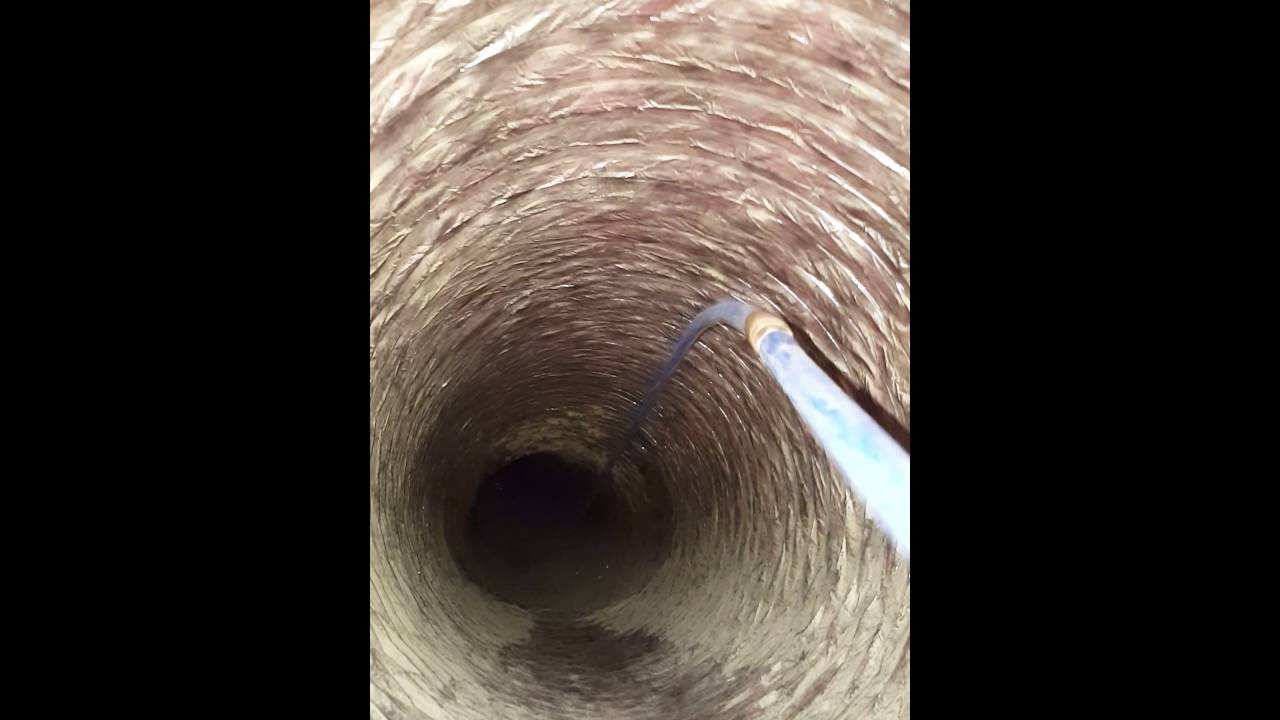

11 Ways To Completely Revamp Your Commercial Air Duct Cleaning Near Me Benzvac Llc

Building owners don't upgrade HVAC systems simply because they want the latest HVAC technology; rather, they want to improve perceived shortcomings with existing systems. Which means the jumping off point should be a comprehensive assessment of the prevailing system. A detailed survey and inspection of all major system components should assess condition, age group, expected remaining useful existence and efficiency. This should add a review of original building drawings and maintenance and fix records. Performance screening fireplace and chimney cleaning or nondestructive testing may be warranted for main equipment components or ductwork, systems and including piping.

It is important to investigate the prevailing system to determine if the system is leading to comfort problems. Many HVAC systems installed in the 1950s and 1960s were only intended to offer a moderate degree of cooling. Nobody expected a program to provide a continuous temperature year-round irrespective of outside conditions.

Since high energy costs often justify HVAC upgrades, historical energy consumption should be compared against industry benchmarks of dollars or BTUs per sq . foot for equivalent types of services. This comparison will show how efficient a building is usually and can identify possible target values for improvement. It may also indicate that, although an HVAC system is 25 or even more years old, general operating costs may be much like newer buildings, to ensure that a complete system replacement may not be warranted predicated on energy savings. In cases like this, replacement of selected parts might be the very best approach.

For some apparatus, such as centrifugal chillers, current gear is significantly more efficient than units installed 20 or even more years ago, using 30 to 40 percent less energy than older versions. However, dependant on the hours of procedure of the equipment, these savings alone might not justify replacement due to the high capital costs of new equipment.

Another consideration in evaluating a preexisting system is whether it uses an obsolete technology. Building automation systems possess evolved considerably during the last 10 to 15 years. Despite having systems that are working reasonably well, it might be hard to get parts or to find service personnel acquainted with older technologies. In addition, fresh systems may have features that the older systems lack but that would enhance mechanical system procedure and improve occupant comfort and ease.

Compliance with codes and regulations is another key concern. Structures built from the past due '70s to the mid '80s were often made to offer lower outside air amounts than required by current codes. Replacement of a person HVAC system component might not necessitate compliance with the new codes; however, this can be desirable to alleviate concerns that lower outside air flow quantities http://www.askmap.net may result in indoor air quality problems.

A comprehensive HVAC system analysis is necessary to evaluate the effect of increasing the exterior air rate. It is usually much less simple as rebalancing the atmosphere handling systems to supply additional outside atmosphere. Increasing the outside air will increase heating and cooling loads, that your existing heating and cooling plant and related distribution systems may not have adequate capacity to serve.

In the event a comprehensive system replacement is to be undertaken, compliance with the existing codes will likely be needed. HVAC upgrades should be carefully evaluated to look for the full degree of code-needed upgrades; this work could make the project considerably more costly than originally expected.

Consider one owner who was simply contemplating a major building renovation, including mechanical program upgrades. The prevailing water-cooled air-conditioning products on each floor were not sized to handle the levels of outside air presently required. Although the equipment was in fair condition and could likely have continued to operate for several years, the dog owner elected to replace the units therefore the building would meet up with the new ventilation regular, as well concerning avoid future disruption if replacement was required following the building was completely occupied. Because of this, other system parts, such as cooling towers and pumps, also had to be replaced.

Environmental regulations may influence HVAC upgrades. In 1996, the CLIMATE Action mandated a ban on the produce of CFC (chlorofluorocarbon) refrigerants, that have been used in virtually all large chillers produced until the first '90s. Some CFC refrigerants are still relatively widely available on a recycled basis; others are scarce or are very expensive. An owner with a CFC chiller should think about refrigerant issues in deciding whether to replace the equipment.

The Right Approach

After the system assessment is completed, a key question is if the major problems could be addressed by changing components or if there are inherent limitations in the system that can't be rectified without a major system renovation or substitute.

A major advantage to a systems approach is that it creates it possible to redesign and optimize the HVAC system. For instance, a fresh HVAC system might be able to utilize smaller ductwork than that which presently exists. In an workplace with a congested ceiling plenum - where additional space is needed for distribution of data cabling or new fire sprinkler systems - this furnace duct cleaning may be a significant benefit. It may also be feasible to create a new system to correct inherent comfort problems with an existing system, such as limited capability to control temperatures on a localized basis.

A variation of the systems approach is to mix HVAC program upgrades with other building upgrades, such as light retrofits. Upgrading existing light systems to more energy efficient lamps and ballasts will certainly reduce the cooling load for most facilities. This may allow new HVAC systems to be downsized, with a corresponding decrease in installation costs as well as operating costs.

Future building uses should be considered as part of every HVAC upgrade task. For example, if a single-tenant building https://www.washingtonpost.com/newssearch/?query=HVAC with one operating schedule is usually to be converted to a multi-tenant building with a wide variety of schedules and cooling requirements, the new use may require multiple smaller sized systems. http://www.bbc.co.uk/search?q=HVAC Changing to a different use type, such as from retail to workplace, will also have main implications for devices size and configuration because of different load, ventilation and control requirements.

Even with replacement of individual program components, future uses should be considered. For instance, with substitute of a cooling tower dedicated to a central chilled water plant, it could be desirable to install additional capacity that can be utilized to mold removal New Jersey serve individual tenant supplemental cooling equipment.

Potential Pitfalls

HVAC upgrades often have significant implications for additional building systems. Changing the HVAC system will often require major electric distribution modifications. If the electric distribution system includes obsolete equipment that can not be expanded or if it generally does not meet current codes, significant extra upgrades to the electric system may be needed, at substantial cost.

Operations and maintenance requirements will often be affected by HVAC upgrades. Generally, maintenance requirements will initially decrease when fresh systems are installed. Nevertheless, sometimes functions and maintenance requirements of a new system may require major changes in methods or personnel. Existing operating personnel may not have the abilities http://query.nytimes.com/search/sitesearch/?action=click&conten... to operate and maintain the new systems, or might not have the mandatory licenses from the local jurisdiction. This might necessitate some mixture of training, hiring or outsourcing. Similar problems may arise for assistance contractors. Also if the company that worked on the original systems did an excellent job, it is important to verify they have the skills and experience to maintain the new system.

Physical building constraints will more often than not have a major influence in HVAC upgrades. A fresh HVAC system may necessitate more equipment area space or vertical shaft space for ductwork or piping, or may require additional space in various other places that must be recinded from occupied areas. This might have a significant impact on the features of the area or may reduce local rental income.

A primary consideration prior to undertaking any building upgrades is the potential disruption to occupancy. For HVAC systems, main upgrades may take some or all of the system out of support for an extended period. Unless the building is unoccupied, this might not be a realistic course of https://www.zeemaps.com/map?group=4218198&location=Boonton%2C%2... action. Often, partial system replacements could be manufactured and phased so that work is limited to unoccupied portions of a service or only occurs during nights and weekends when the service is not occupied. However, to do this, the existing system must be carefully evaluated to reuse as much of it as possible, especially within occupied spaces.

Project planning also needs to consider seasonal cooling and heating requirements. Ideally, replacement of heating gear should occur during the cooling time of year and vice versa. If this is not possible, huge central systems with multiple units serving a common load might be able to operate most of the time with a portion of the models operational so that equipment can be replaced one device at the same time. Project schedules must also consider manufacturer lead occasions, which may be four a few months or longer for major equipment such as large chillers or boilers.

An HVAC upgrade task is a substantial business decision requiring a major capital investment. The outcomes of an engineering assessment may suggest that a complete system

© 2024 Created by PH the vintage.

Powered by

![]()

You need to be a member of On Feet Nation to add comments!

Join On Feet Nation