Welcome to

On Feet Nation

Members

Blog Posts

Viagra: A Revolution in Treating Erectile Dysfunction

Posted by freeamfva on April 29, 2024 at 9:44pm 0 Comments 0 Likes

Viagra, also known as sildenafil, has revolutionized the treatment of erectile dysfunction. This article explores the journey of Viagra, its impact, and its role in modern medicine.To get more news about herb viagra pills, you can visit herbal-hall.com official website.

The Discovery of Viagra

Viagra was initially designed for treating heart-related chest… Continue

Top Content

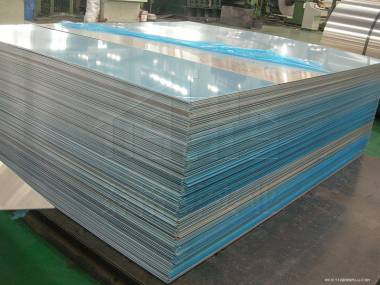

What is the purpose of painting aluminum sheets and how to do it by tigersalu.com

Sprayed 5052 aluminum panels are aluminum panels that have been sprayed with various colors of fluorocarbon paint (or polyester paint) on the surface before being baked and cured at a high temperature. It can be used for a variety of purposes including exterior and interior wall decoration, indoor ceiling decoration, and so on.

It is widely used in a variety of industries, such as construction, decoration, and transportation, because of its excellent corrosion and weather resistance, strength, and durability, as well as its beautiful appearance, ease of production compared to anodic oxidation and environmental protection, among other characteristics.

It is necessary to chemically clean and etch aluminum supplier alloy profiles before painting in order to remove the adhesion of grease surface, natural oxide film, and dust and other pollutants.

Aluminum plate spraying is typically subjected to three layers of coating and two baking processes:Spraying aluminum plate three layers of coating, two baking fingers: when spraying aluminum supplier plate, open three groups of guns, the first primer, the second color paint (fluorine or polyester paint), the third coat of protective topcoat (varnish), two baking fingers: when spraying aluminum plate, open three groups of guns, the first primer, the second color paint (fluorine or polyester paint), the third coat of protective topcoat (varnish), two baking fingers: when spraying aluminum plate, open three groups of guns,However, the coating production line now consists primarily of three layers of baking followed by two layers of coating baking.

It is common for the surface of powder coated aluminium veneer curtain wall to be polluted. The scope of the application

Aluminum plate is a lightweight metal with a very smooth surface. Because most paints cannot be sprayed directly onto aluminum company plate, patterned aluminum plate is more susceptible to paint loss and peeling. It is necessary to use specialized paint in order to accomplish this.

aluminum company plate is painted with ED1000 epoxy primer, which has a variety of characteristics and is designed for the surface of aluminum plate. Aluminum, stainless steel, aluminum alloy, galvanized sheet, and other metals are all suitable for use with this product. Save time and effort by avoiding sandblasting and sanding the substrate, and only removing the surface oil instead of removing the entire surface oil layer.

It can be used in conjunction with fluorocarbon paint, polyurethane paint, acrylic paint, and other types of paint. Polyvinylidene fluoride resin (KANAR500) for use as a topcoat and varnish for fluorocarbon coatings. Coats are typically divided into two, three, or four layers. Fluorocarbon coatings have excellent corrosion and weather resistance, and they can withstand acid rain, salt spray, and various airborne contaminants.

In order to remove oil and grease from the surface of the aluminum plate, first wipe it down with solvent; then spray ED1000 epoxy primer in 1-2 coats, and spray top coat after 24 hours of solid drying; the top coat should be selected according to the actual environment. Matching scheme that is frequently used.

The electrostatic powder coating process is carried out in the following manner: with electrostatic powder spraying equipmentAfter powder wikicoating /wikispraying to the surface of the workpiece, in the electrostatic effect, the powder will be uniformly adsorbed on the surface of the workpiece, resulting in a powder coating; powder coating after high-temperature baking leveling curing, into the final coating with different effects (different kinds of powder coating effect); patterned aluminum spraying effect in wikimechanical /wikistrength, adhesion, resistance to wikicorrosion/wiki, aging resistance

The purpose of pretreatment is to remove oil, dust, and rust from the surface of the workpiece, as well as to generate a layer of corrosion resistance on the surface of the workpiece, which can improve the adhesion of the spray coating phosphate layer to the workpiece. The following are the primary process steps: oil removal, rust removal, phosphating, and passivation. It is possible to generate a uniform and rough gray phosphate film on the workpiece by pre-treatment, which not only protects the surface from oil, rust, and dust, but also prevents rust and increases the adhesion of the spray layer on not only the original silver-white glossy surface but also the original silver-white glossy surface.

© 2024 Created by PH the vintage.

Powered by

![]()

You need to be a member of On Feet Nation to add comments!

Join On Feet Nation