Welcome to

On Feet Nation

Members

-

Sarah Morgan Online

-

smithmorgan Online

-

jack Online

-

stephen005 Online

-

DANGERBOY Online

-

Wesley Online

-

Michael Online

-

oodles erp Online

-

hr executive search firms Online

-

Cassandra Online

-

Alex Online

-

Christopher Online

Blog Posts

BEST RELOADING BRASS NOW AVAILABLE IN STOCK

Posted by smithmorgan on September 19, 2024 at 8:45am 0 Comments 0 Likes

BEST RELOADING BRASS NOW AVAILABLE IN STOCK

Posted by smithmorgan on September 19, 2024 at 8:45am 0 Comments 0 Likes

Top Content

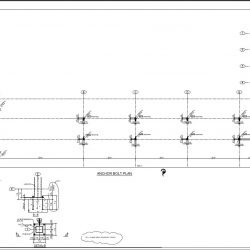

What is Rebar detailing and shop drawings process?

What is Rebar detailing and shop drawings process?

This is mainly a science of preparing a whole set of drawings of various things including steel, iron, etc. reinforcement for concrete construction. These drawings indicate the description, bending shapes, measurements, shape, and size. Detailing of Rebar is the discipline of creating shop drawings of steel reinforcement for construction.

By contract implementation of Shop Drawings the intent of the Design Drawings for the workers of iron. They call out the description, bending shapes with dimensions, quantity, and laps of the reinforcing steel. Various applications are applied to produce bar bending schedules which can directly feed into the machines of CNC that bend and cut Foundation details the rebar to the required shapes.

Rebar reconciliations is assigned to contractors in house teams, rebar detailing companies and cut and turn companies. The station in the Middle East and India is a vast majority of Rebar Detailing Companies.

How is it implemented?

Once the engineers are done with a set of drawings, the next part is giving shape to the steel bar. The plain steel bars are fed into CNC machine where they are being cut and bent into desired shape and size. Then the pieces are arranged according to the drawings.

Why is it needed?

As I stated earlier, the process gives mechanical strength to the concrete structure. No matter, how strong the concrete is in compression, it is fragile in tension. Rebar detailing distributes the whole pressure of concrete uniformly. In this way, the process saves ceilings from falling.

Areas where rebar detailing can be implemented:

Huge infrastructures: Footing detailing The process is widely used for the design and construction of hydropower stations, highways, water treatment plants, electrical power plants, etc.

Commercial structures: In the building of residential houses, public or commercial utility buildings, refineries, malls, etc.

Industries: for the foundation and base of different types of industries.

In most of the cases, the rebar detailing is handed over to in-house teams or civil contractors. Most rebar detailing service companies are located in the Middle East region. Here one can easily find a rebar detailers at meager prices.

Diecastings is a process of manufacturing that can produce complex metal parts of different parts through reusable molds known as the dies. The process involves the use of metal, furnace, machine, and the die itself. When it comes to aluminum of this kind, one need to continuously change, innovate, and grow with the changing pace of the innovative scenarios. With skilled professionals and sound practices, the premium manufacturers win the battle. The clients prefer the ones with extended warranties, superior warranties, and improved durability.

The Useful Element

Aluminum is the third most fruitful element on earth as it is incredibly versatile that can be made into a wide range of diverse and useful products, which is known to as the aluminum casting. This process involves the melting of an aluminum alloy, which is heated to 1300 degrees Fahrenheit. The molten metal will be poured into an iron mold till it is filled to the brim. Once the metal is cooled the iron cast is removed. Most frequently, this activity involves power coating and grinding to make it a fully functional product.

What Makes It Different

The aluminum parts of this kind are even stronger as compared to the steel. To meet the end results, it is important to match the expectations of the clients starting from designing, planning until the execution part. They are responsible roles towards the final product. Assembling and testing of the finished products are done to maximize the productivity and ensure getting a satisfactory output. The process of engineering needs to be reliable and economical to match up with various clients as well as their demands.

The final touch-up and surface material of material make a large difference to the end output. Premium manufacturers consistently take care of such detailing to guarantee maximum advantage for their clients. When supported by technical assistance, and services that enhance its credibility, aluminum diecastings gives the manufacturer an added benefit. The finishing of this sort is another important aspect to be taken care of by the supplier or manufacturer, and hence achieving a better look.

What Everyone Needs

One requires highly http://edition.cnn.com/search/?text=Rebar Detailing Services | Reba... knowledgeable and skilled professionals to undertake every job of this sort. Be it zinc or aluminum, the functions and procedures remain same with the difference in the metal. It is not just delivering the products to the clients; rather it has more layers to it. Right from the after sales up to servicing, the whole thing matters to give a name to the manufacturer or supplier. This also needs specific tools and procedures to acquire the desired results. The products can range from spares, metal handicraft, equipment, and much more.

© 2024 Created by PH the vintage.

Powered by

![]()

You need to be a member of On Feet Nation to add comments!

Join On Feet Nation